IDEC Systems are able to run a large 3+ story building on fans, cooling tower, indirect water pumps and evap pumps for 98% of cooling season supplemented by less expensive 1st cost and operating cost chiller.

Example HAFB

From this type of system the end result is a typical payback of 3 years on 30,000 cfm and above airhandlers.

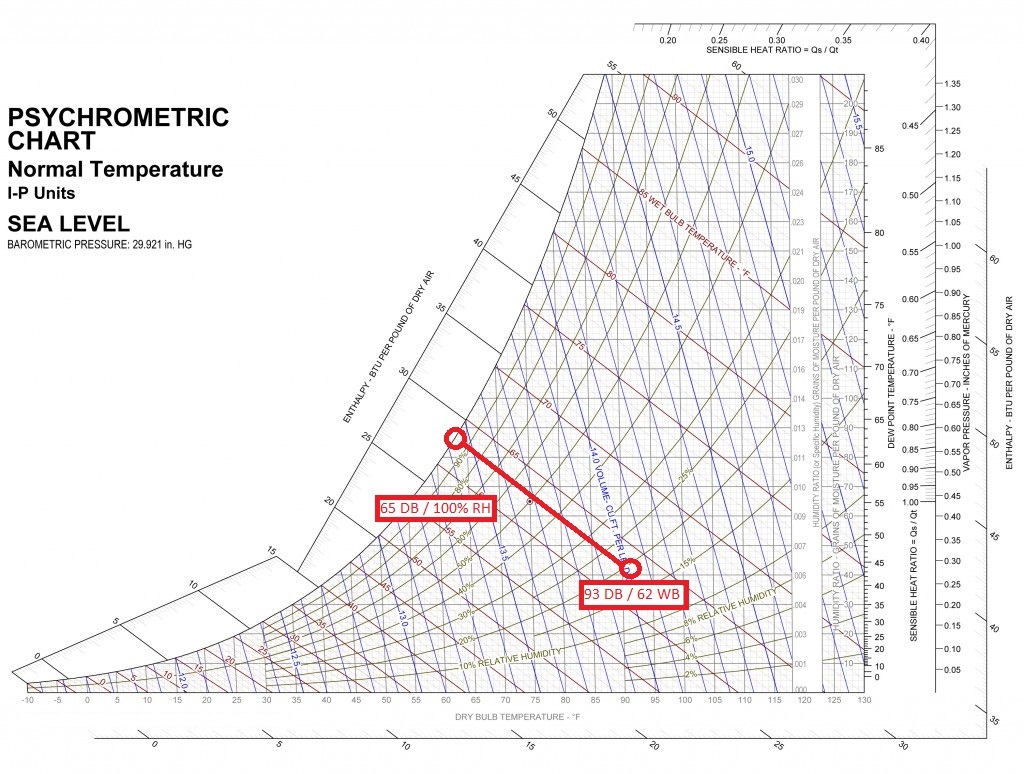

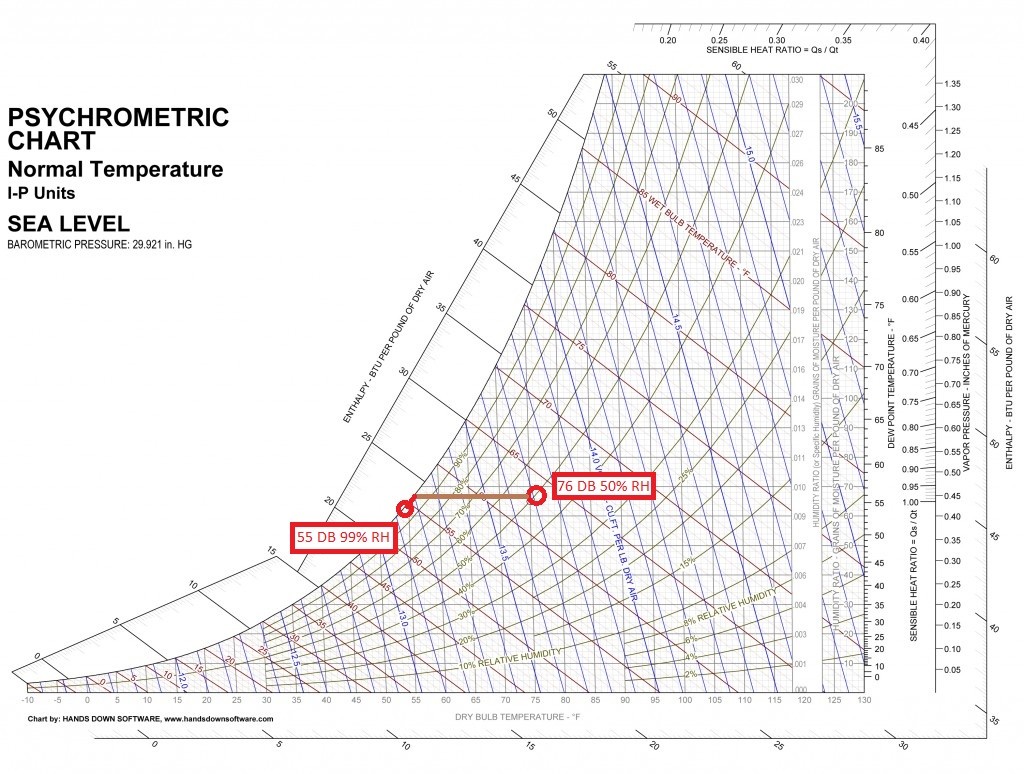

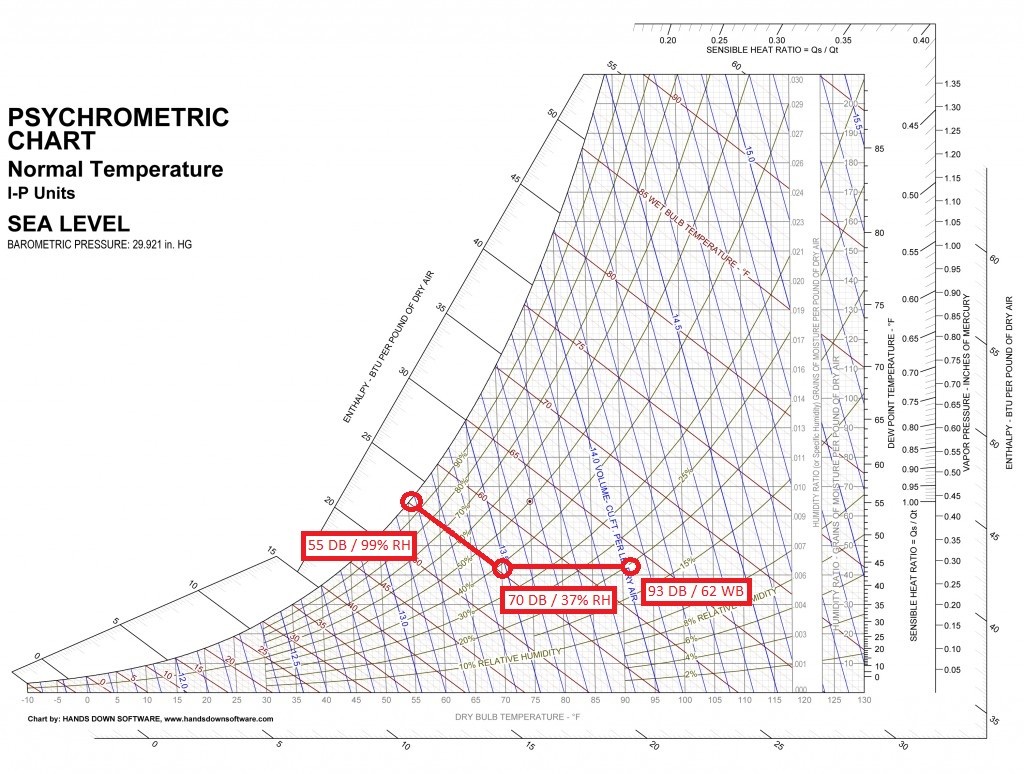

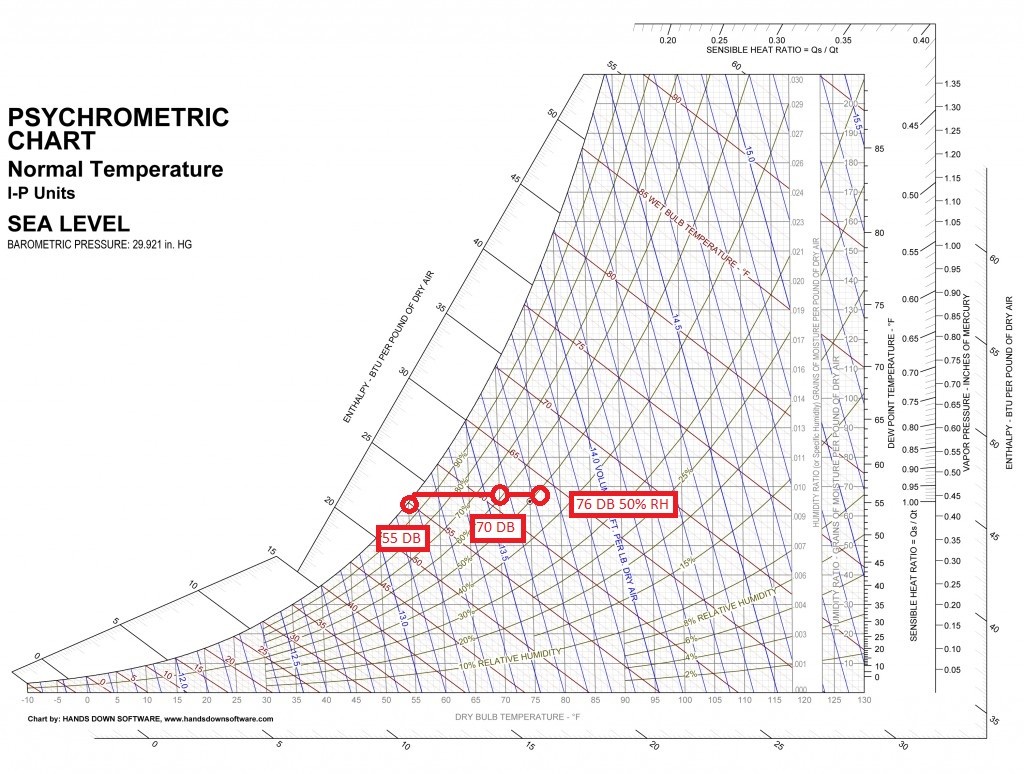

Stages of IDEC

1. Economizer

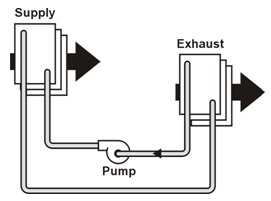

2. Economizer + Indirect Cooling Coil

3. 100% OSA + Indirect Cooling Coil + Direct Evap (Stage ICC Coil not Direct Evap for control)

4. Mechanical Cooling + Indirect Cooling Coil

Design considerations.

- Once you go to stage 4 stay on stage 4 for the day to avoid nuisance changeovers.

- Turning on and off evap pump can shorten pad life and burnout pump. Use bypass damper on stage 3 if temperature drops below setpoint with ICC coil turned down. If bypass damper is open for extended period of time then turn off evap pump.

- Dump evap sump nightly or every 3 days to eliminate growth on pads and sump.

- Amount of water usage for evap cooling is significantly less than amount of water used to power turbines etc for mechanical cooling of traditional system.

- Auto flush and fill system will eliminate reasonable chance of legionella disease.

- Media holds water like a sponge, typical 20,000 cfm unit uses 2.5″ overflow drain, 50,000 cfm unit uses 3″ overflow drain, 75,000 cfm unit uses 4″ overflow drain.

New media must be flushed and dumped about 6 times before resin is cleaned enough to minimize water carryover.